Background

Dalfsen is a town of 28499 people (as of January 2019) in the northeast of the Netherlands, located in the province of Overijssel 97km/60mi east of Amsterdam and 25km/15.5mi west of the German border near Hardenberg (both measurements in linear distance).

Dalfsen has a station on the Zwolle-Stadskanaal rail line, an electrified mostly double-tracked main line crossing through the northeastern Netherlands on 107km/66mi. Opening between 1903 and 1905 the rail line was eventually cut down to Emmen in the late 1900s. The line is exclusively used by regional passenger trains at speeds of up to 140kph/87mph.

The vehicles involved

The day before the accident a rented elevated work platform had been used by a landscaping company to uproot a tree to the south of the railway line on the property of a local farm. The version used was a Grove MZ 90 CR, a relatively large elevated work platform allowing work at up to 27m/89ft above ground. The platform sits on a pair of caterpillar tracks for propulsion and has a listed weight of 20 metric tons. The platform can be operated remotely from the elevated platform and has a top speed of about 1kph/0.62mph.

In 2012 Arriva, a British subsidiary of the DB (German national railway) had taken over the operations on the Zwolle-Stadskanaal rail line from the Nederlandse Spoorwegen (NS, Dutch national railway) after winning the bid against competitors in part with promises of better service and more trains running on weekends. After signing the contract for the services in 2007 Arriva ordered 14 fourth generation Stadler GTW specifically for the job, the first of which arrived just in time in summer 2012. The Stadler GTW is a three (GTW 2/6) or four (GTW 2/8) car electric multiple unit made between 2006 and 2017. The trains are easily recognizable by a short two-axle power car sitting in the middle of the train (GTW 2/6) or behind the second car (2/8). This arrangement simplified construction and eases maintenance at the price of slightly less usable train length. The four-car version involved in the accident weighs 86 metric tons empty at 55.94m/184ft in length and can seat 155 people in a two-class configuration. As Arriva operates the 4-car trains with a conductor on board the trains are set up for a two-man crew (driver and conductor). The trains receive 1500V from the overhead catenary and have a power output of 1100kW/1496hp through the two driven axles of the power car, enough for 140kph/87mph. The fourth generation GTW, which has been sold to a number of countries including Switzerland, the USA and Spain, were engineered to the highest standard of crash protection at the time (as required by Dutch law, coincidentally), offering the best possible protection by means of buffers, crumple zones and anti-climb elements (structures keeping an opposing rail car from mounting the frame of the train). The unit involved in the accident was numbered 10520 and christened “Ilse DeLange” after a popular Dutch singer.

The accident

On the 23rd of February 2016 workers pack up their equipment at the farm on the eastern edge of Dalfsen at around 8am, having finished their work the previous day. The rented elevated work platform is going to be picked up by a truck on the northern side of the tracks about an hour later as the small dirt road the workers are on is inaccessible to the truck. At approximately 8:40am one of the workers climbs into the basket of the vehicle, which is parked on the southern side of the level crossing, and turns it around for the basket to face the tracks. At 8:43am a westbound regional train passes the crossing, once the barriers raise up again the worker starts moving the platform through the crossing. When they had brought in the platform the previous day they had measured the time between trains and noted down 10 minutes, unaware that the trains run on an uneven schedule. They didn’t actually have 10 minutes this time, they had 6.

The eastbound train had departed Dalfsen station at 8:33am with 7 people on board (passengers and crew) and was about to go through a sprawling right hand turn towards the crossing obscuring it until it was only a few hundred meters away. By approximately 8:48am the worker controlling the platform from the basket was already past the crossing himself while the vehicle itself had barely entered it. He could now look down the track towards Dalfsen beyond the curve and suddenly saw a train bearing down on him. The crossing, not engineered for such slow vehicles, hadn’t even activated the first stage of the closing procedure yet.

The train was travelling at 140kph/87mph, requiring a (calculated) distance of 800m/2625ft to get to a standstill. The worker later testified that he kept pushing the button to move the platform forwards as the long boom had no chance of clearing the tracks in time. At the same time he waved his free arm to try and alert the driver of the train. The driver did spot the obstruction at a distance of 175m/574 and triggered an emergency stop within the same second, but it was too late. At 8:50am the train struck the side of the work-platform right in the center at almost 90°. The main section of the work platform was ripped off its tracks, obliterating the train’s driver’s cab in an instant. The boom and basket tore off the vehicle as it got caught on and unearthed a support pole of the overhead catenary (now travelling at approximately 107kph/66mph within a second of the impact) while debris from the initial collision got caught under the train’s leading wheels and derailed it to the right. The train’s second car got caught and uprooted another catenary pole as the leading car veered off the tracks to the right at an increasing angle, digging into the soft soil and falling over just beyond the adjacent farm before coming to a rest. The couplers held the train together as it fell over as a whole, lying across the tracks and the grassy fields on either side in a curve. The work platform’s three main parts (frame, main section and boom) ended up to the left of the tracks at 30–60m/98–190ft) from the point of impact while the train covered 150m/495ft before it came to a rest. Between the two parts of the wreckage and the level crossing lay a field of debris, dotted with craters in the ground where the catenary poles had been pulled from the ground along with their foundations. Two long trenches stretched from the tracks to the leading car of the train, ending shortly beyond the point where the bogies had torn off the car. The whole sequence from the first impact to the train coming to a rest had taken just 7.5 seconds.

The driver was the sole fatality of the collision, with the six people aboard his train being injured (two of which severely) and the worker jumping off his vehicle at the last second, suffering minor injuries.

Aftermath

Responders reached the scene a few minutes after the collision, finding the path of destruction leading them along the damaged tracks past the remains of the elevated work platform down to the toppled train. Approaching the train from the back it seemed largely intact, the cars had remained coupled together and the rear ones remained structurally intact. It was only when responders made their way around the front of the stricken train that they realized the violence of the collision, as the driver’s cab of the train had ceased to exist except for a small stripe of bent up floor. The rear wall of the driver’s cab gave the train’s front end a sudden, vertical end. The coupler, buffers and white pieces of metal and fiberglass strewn around the site ahead of the train were all that was left of the aerodynamic cabin. The conductor, who suffered severe injuries, was flown to a hospital while another severely injured passengers was taken away by ambulance. The remaining passengers were treated on site and released. The fact that the train had run at not even 5% capacity had drastically reduced the consequences of the accident, while it’s unlikely that a higher death toll would have had to be mourned there obviously would have been much more injured people, as the injuries came from the passengers being thrown around the interior of the train as it struck the obstacle and subsequently rolled onto its side.

The worker who had operated the vehicle was detained at the site and taken to a police station for questioning, it was fairly clear that he either was at fault for or at least played a significant role in the accident. Investigators inspected the remains of the work platform’s propulsion system and found no trace of a defect prior to the collision. This matched the statement of the worker who said he tried to move the platform out of the crossing until abandoning it at the very last moment. Blame was thus shifted from the equipment to the workers, who had relied on a baseless sense of security that trains always ran at the same interval, something easily disproven with a look at the timetables of the surrounding stations. They took the 10 minute gap between two trains on the prior day and the fact that the barriers were up as sufficient proof that they had enough time to cross, when neither of these things proved anything. At a dutch level crossing the lights come on a set time before the barriers close, enough time for pedestrians, cyclists cars or even buses to clear the tracks. The system is not engineered to accommondate specialized equipment that moves at (comparatively) a snail’s pace.

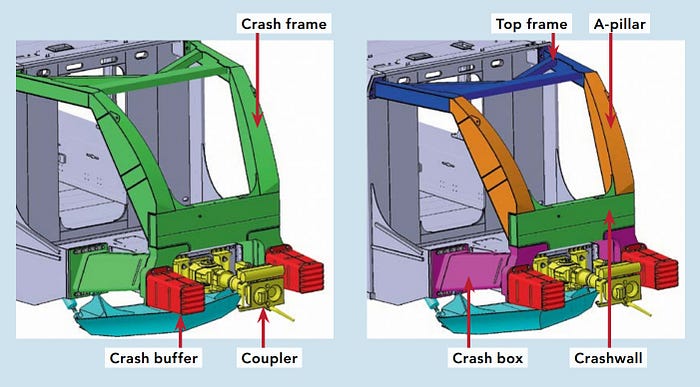

The night after the accident the train and the remains of the work platform were removed from the site and taken to a warehouse for further inspection. Taking measurements on the intact end of the train and an identical work platform investigators lined up the two vehicles and found that the first part of the crash-structure, energy-absorbing buffers and the coupler, had been largely disabled in the collision. Usually the buffers and coupler compress to absorb energy, once they are overloaded dedicated “crash boxes” behind the buffers deform/collapse to absorb further energy. Meanwhile a “crash frame” is meant to provide survival space to the driver, consisting of the vertical crashwall below the windshield, two massive A-pillars on either leading corner of the cabin and a top frame supporting the roof with triangular bracing. This is meant to direct most forces in an impact past the driver into the massive frame of the train, onto which the cabin is added on up front. Continuing the frame all the way to the front would mean less energy absorption in a collision with a weaker obstacle and also higher forces inflicted on the people aboard (similar to why cars aren’t meant to be completely rigid).

The buffers had struck one of the caterpillar tracks and the (movable) chassis of the platform, causing the coupler to slip between the two parts and absorb little energy before it was torn off the train in its entirety. This is why it was found sitting in the wreckage largely undamaged/uncompressed while the buffers had been severely deformed. The impact of the heavy main section of the platform into the driver’s cab itself overloaded the engineered higher strength crash frame, bursting welds at the top and bottom of the A-pillars and folding the upper half of the driver’s cab inward as the lower section crumpled away. Severe deformation at the attachment points of the A-pillars and roof frame showed that, in an instant, the A-pillars caved in and the roof buckled up at the welds in a scissor-motion, eliminating survival-space for the driver within a fraction of a second. The A-pillars, crash boxes and top frame were found among the wreckage in different places, pointing to the high velocity they still carried as they tore off the train.

After a thorough investigation of the train’s structural engineering both on the destroyed and the intact side (this section makes up a majority of the 117 pages strong report) the investigation concluded that the death of the driver can’t be blamed on faulty engineering or construction of the train, despite a faulty weld being found on the train. Impacting (in simplified terms) a 20 metric ton steel block was just more than a passenger train could ever be expected to handle, plus the fact that the shape of the obstacle lessened the efficiency of the crash protection structures. While a criminal investigation was split off and focused on the worker who had operated the work platform the main investigation focused on level crossing safety, pointing out two previous accidents in the Netherlands where Stadler GTW trains had struck trucks on level crossings (a milk truck and a low-loader carrying concrete slabs) with less severe consequences. The former’s train had shown the same welding imperfection, proving that this played no role in the outcome of the collision at Dalfsen. The report even particularly points out a collision between a passenger train and a tank a few years prior in which the driver survived (with severe injuries). The report mentions that it is important that drivers at least attempt to retreat from the cabin, something that was impossible at Dalfsen due to the quick succession of events (3.5 seconds between the emergency stop being triggered and the impact) but is usually recommended to increase survival-chances. Unfortunately, it is still common for drivers to “freeze” in shock or even have a “down with the ship”-mentality, being unwilling to abandon their post on the irrational thought they could do more than trigger a stop.

The report points out that elsewhere in Europe steps have been taken to reduce the risk posed by large/slow vehicles at level crossings beyond the fitment of even remote level crossings with barriers (which the crossing at Dalfsen had). The report shows examples from the UK where large signs tell drivers of certain vehicles to stop and call the local dispatch center with a provided telephone, something considered impractical for the Netherlands due to the centralized character of their rail traffic control and the high amount of traffic and crossings.

Another example given is that of localized radar found at some German level crossings, trains cannot approach the crossings in Germany to less than 1500m/4900ft if the crossing isn’t cleared (a task fulfilled by crossing guards until widespread automation took place). A downside of the German system is that it extends the time the barriers are down from around 1–1.5 minutes to 3 minutes, something also deemed impractical for most level crossings (except ones in particularly low traffic areas). Despite the mentioned drawbacks the investigation still advised ProRail (the Dutch railway infrastructure operator) to look into these or other means of increasing the safety of level crossings, potentially with partial adoption (like providing a phone number of the dispatch center at crossings). For the time being tracked vehicles were banned from Dutch level crossings (as these are usually significantly slower than wheeled counterparts), vehicles with particularly low ground clearance and long wheelbases require special permission to use selected level crossings to avoid a vehicle beaching on the track, and any vehicle incapable of clearing the crossing in 15 seconds (the minimum time between the lights coming on and the train reaching the crossing) has to arrange the crossing with ProRail and be given a specific time frame to perform the operation.

The train line was repaired within a week of the accident, while the work platform and train were written off. Arriva ordered three additional middle cars to turn three of their GTW 2/6 into 2/8 (independently from the accident), one of which effectively replaced the destroyed train. Furthermore, in 2017 Arriva ordered 18 Stadler Wink, the GTW’s successor, which allow Arriva to shift GTW’s onto the Zwolle-Stadskanaal rail line from elsewhere. On the 12th of September 2017 the then 23 years old worker was sentenced to 240 hours of community service for negligent cause of bodily harm and dangerous interference with rail traffic, 2 weeks later the sentence was cut down to 100 hours.

Video

_______________________________________________________________